Execution of different types of glass frameless facade with special conditions and offers

curtain wall manufacturing companies | listen to this article:

The execution of all types of glass frameless facade with special conditions is possible. For example, if your workload is high or the building is special, So the executor of the glass frameless facade will set special conditions and offers for you.

Types of glass frameless facade in the industry

The glass frameless facade is made of large glass that is glued to the frame. Usually, Executors glue this type of façade by silicone glue.

People who like to have a view from the inside of the building can use a variety of frameless glass facade.

Also, Using different types of frameless glass facades is very useful in addition to the appearance and beautify of the building.

Advantages of frameless façade in the industry

Frameless façade is a building facade that has different capabilities. The frameless facade has a special position in the facade and building industry.

For instance, the advantages of using frameless facade in the building include:

- the surface of the building is visible in the form of uniform glass

- No restrictions on the selection of frame

- Lack of detection of opening frames at the exit of the building

- Easy installation from inside

- No scaffolding required for installation

- Excellent sealing

- Create a boundary between the facade and the building

and so on…

Most frames and windows made of frameless have a touch button through which you can open them easily. Also, These doors and windows designed to open of the side or of the middle.

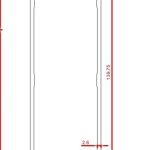

Production of frameless façade

Engineers design and produce Frameless façade in various stages and in various units in the factory. for example:

Anodizing unit

In this unit, profiles and frameless parts are packaged. then Our coworkers insert packaged parts into the tub then before substructure stage, they dry the submerged profiles.

The goal of this unit is to prevent frameless profiles from corrosion.

So, In this unit, the frameless will have these features by placing the anodizing layer.

- Lightness

- Resistant to corrosion and any abrasion

- Electrical insulation

- Heat conduction insulation

- and so on

Façade Paint unit

Dried profiles are ready to paint. Our coworkers transfer them into a special cabin to spray paint.

So The paint is sprayed on the profile by electrostatic devices. (Paints are usually in powder form.)

Then, the profiles are placed in the furnace and after leaving the furnace, they are sent to the next stage.

Factory units

In conclusion, the production stages of the frameless façade is as follows.

- Cutting frameless façade

- Milling

- Pressing, drilling, grooving (for different connection points)

- Assembly (for installation)

You can contact us to buy and sell these products.

Types and examples of curtain wall construction and execution

Types and examples of curtain wall construction and execution Building Facade|facade engineering|facade materials Ceramics Facades|Handrails|Terracotta Facade|Thermowood WPC Wood Plastic|facades glass|dryfacade (Aluminum Louvers) Detailed technical and executive information for those interested

Also, Here are some of the capabilities of this company:

Valid Aluminium Company site

aluminum company producer Above all factory in Manufacture aluminum

profile windows & door aluminum

Details of the Valid Aluminium Company of factory products

Curtain Wall|Frame less glass facade|Aluminum louver Sky light glass|Dry ceramic|Dry stone|aluminum profile Glass Aluminum handrails|Composite sheet|Wood-plastic(WPC) Spider|Facade Design & Concept Engineering Interior Design

related content:

Frameless glass| Production of various types of Frameless glass

Mr : Valid : 0016042564683

Mr : Valid : 0016042564683

Aluminum roof Louver Distribution Center